When these plates are pressed together, torque is transmitted from the input to the output members. These clutches contain a pack of annular discs or plates, and alternative plates are circumferentially grooved internally and externally to match up with the splines in the input and output drive members respectively (Fig. Multi-plate clutches are extensively used along with band brakes in epicyclic compound gear trains of automatic transmission system to lock different stages of the gearing or gear carriers together, so that a combination of gear ratios are available. Multi-plate Hydraulically Operated Automatic Transmission Clutches As the linings wear increases, the distance between the cover pressing and pressure plate become excessive, so that the axial thrust begins to decline.Ģ4.8.3. As the friction linings wear, the spring diaphragm becomes more dished so that a larger axial clamping load is applied initially. During engagement of the clutch the diaphragm bears against the outer ring, and during disengagement the reaction load is taken by the inner ring. In order to accommodate the change, the diaphragm pivots and rolls about the fulcrum rings. Multi-plate diaphragm type clutch.ĭuring operation, due to engagement and disengagement of the clutch, the diaphragm cone angle changes continuously as wear occurs. These rivets also hold a pair of fulcrum rings on either side of the diaphragm.įig. Shouldered pivot post, riveted to the cover pressing locates the diaphragm spring in position. These radial slots divide the disc into number of release levers. 24.17).Ī dished annular disc forms the diaphragm spring, the inner portion of which is radially slotted and the outer ends are enlarged with a circular hole to prevent stress concentration during disengagement. The driven plates are mounted on the internally splined hubs, which splines on the gearbox spigot shaft (Fig. The drive plates are not allowed to rotate independently by using interlocking lugs and slots, which do not permit relative rotational spin, but axial movement. These clutches basically have drive and driven plates. The porous surface of this plate traps the oil, to provide long life and smooth operation. Sintered bronze plates of partially fusing powdered bronze or compressed paper are used in many designs. Generally wet type clutch is used in automatic gearboxes, and is operated by a piston governed by hydraulic pressure.

To overcome this problem the plates are either dished or fitted with small springs to push the plates apart. In this arrangement it is difficult to ensure the disengagement of all plates. Multi-plate spring type clutch.įor the clutch disengagement, the end plate is withdrawn to compress the springs and release the other plates. Thrust springs push the plates together to form a drive.įig. These steel plates may be plain or fitted with cork or friction material inserts and act on inner plates, splined to a hub.

Single plate clutch advantages series#

A cover, bolted to the flywheel, engages by means of slots with a series of lugs on the outer plates. In these gearboxes, a number of clutches hold the various gear elements, and as the clutch diameter in these units is limited, a multi-plate clutch is suitable.įigure 24.16 illustrates the layout of a multi-plate spring type clutch, fitted on early motor cars.

However, a multi-plate type of clutch finds a use in automatic gearboxes.

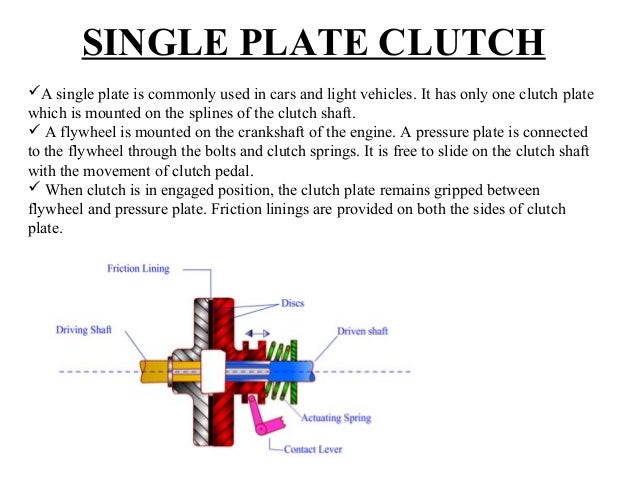

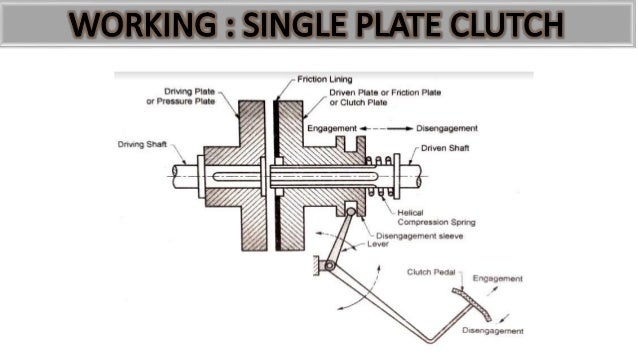

Although this type of clutch has been widely used on cars up to about 1930, the several advantages of the single-plate clutch, specifically its ability to completely disengage the drive has caused a very rare use of a multi-plate unit as a main transmission clutch installed between the engine and gear box. A multi-plate clutch has more than one driven plate.

0 kommentar(er)

0 kommentar(er)